The appearance of cracks on the facade of a panel house is a fairly common occurrence. For the most part, they do not pose a particular threat to the serviceability of the building, but other situations also occur.

To answer the question of what to do if a crack appears in the wall of a panel house , you must first correctly assess the scale of the problem, identify the causes of its occurrence and, based on the data obtained during a qualitative analysis, determine options for resolving the situation.

What if the problem is not in the panel seams?

If during the audit no problems were found with the joints of the slabs, the cause of the sounds may be due to thermal expansion of reinforced concrete structures and their further sudden cooling. However, this is certainly not so easy to determine. It is likely that certain construction standards were violated during the construction of the house. In this case, it is worth protecting the wall from possible temperature changes, and the ideal way for this would be external thermal insulation. With her, the apartment will be warm in winter and cool in summer.

Finishing of apartments in a new building

Decorating an apartment in a new building has its own characteristics.

Before moving on to the key details of the work, you should understand the features of the new multi-storey building. In modern construction, the construction of houses of three main types is practiced:

- Panel;

- Brick;

- Monolith or monolithic brick.

Regardless of construction technology and classification, all new buildings have one unpleasant but common technological feature - the inevitable process of shrinkage. This factor must be taken into account when planning the start of work in order to avoid troubles and wasted funds.

Strengthening walls

In construction practice, the most dangerous phenomenon is when a crack grows. What to do in this case: rebuild the damaged area again or seek help from a professional construction organization?

ATTENTION! If the panel ceiling needs to be repaired, specialists will repair the damage.

The wrapping process is not complicated, but this procedure has a number of nuances, without which it is impossible to talk about the quality of the work done. Stages of repair work:

Legislation

If the root cause of the cracks is unknown, the management company or homeowners association draws up a report. To do this, you will need to write an application to the City Housing Inspectorate and wait for a commission .

ATTENTION! In 2010, the Arbitration Court of the Russian Federation ruled that the management company or housing and communal services are responsible for the condition of residential buildings.

If a conflict arises, it is advisable to file a complaint about the action or inaction of the organization. The legislation of the Russian Federation does not prohibit applying to several government agencies at the same time.

However, the complaint must be supported by an inspection report and other supporting documents that can resolve the conflict. Going to court is considered a last resort. However, a court decision that has entered into force is mandatory.

Danger of a crack in the wall, identification of risks

Having determined the causes of cracking, you can roughly determine the degree of danger of their presence in the wall.

For an objective assessment, you will have to examine the cracks from your neighbors’ apartments and carefully look to see if there have been any redevelopments there. If the relationship is good, the neighbors will show you without any problems, otherwise you will have to collect a commission.

For the most part, the cracks described are harmless. In new buildings, during the first 5 years, while the house “settles”, this is a fairly normal phenomenon, natural shrinkage.

Is a crack dangerous?

Cracks under the conditions mentioned above are usually not dangerous.

Even in houses that are more than a hundred years old, new cracks can form. The reason for this may be increased traffic, and changes in the structure of the soil due to increased humidity or, say, construction work on a neighboring site. In new buildings, there is a high probability of cracks in the walls during the first five years of the building’s operation. This is exactly how long, according to experts, a house needs to shrink.

Of course, cracks can also occur when there are actually defects in construction and building elements, or after reconstruction or major reconstruction of the building. And in this case they can be dangerous.

To find out the level of danger, observe how such a crack behaves. This is not difficult to do. You only need to apply a control strip or plaster mark.

That is, you need to take a little prepared plaster, apply it to a crack the width of your palm and observe this mark for three to four weeks to see if a crack appears on the plaster mark.

Causes

Floor slabs in a panel house (apartment) can be subject to both minor and deep defects .

In order to begin carrying out repair work, it is necessary to find out the causes and nature of the problems. The most likely reasons for the appearance of a crack in an apartment, be it a new building or an old one, are the following:

- Deformation of panels . They arise as a result of operation, since the physical properties of any building material deteriorate over time. As a rule, cracks in panel ceilings expand and lengthen if a number of repairs are not carried out in a timely manner.

- Shrinkage of the building . At the initial level of construction, a process of shrinkage may take place. However, this defect, in most cases, does not pose a danger. As for the appearance of a crack as a result of the natural shrinkage of the structure, it can lead to a partial violation of the rigidity of the entire structure, since the load-bearing capacity weakens several times at once.

It is important to remember that suspended and suspended ceilings will only correct visible defects in the foundation, but will not solve the problem.

Due to the fault of the developer

Fluctuation of pressure on the foundation as a result of uneven settlement of the foundation. This is due to insufficient geological surveys or external factors.

The displacement of the soil under an already constructed structure causes shifting loads, which entails inclined cracks.

Point compression of the soil also plays a significant role in identifying the causes of cracks, especially in new buildings.

Nearby pits, traffic, dynamic influences are factors that influence the displacement, compression and settlement of the soil. There are cases when soil freezing, combined with insufficient flexural rigidity of the structure, contributes to the appearance of cracks.

How to repair cracks in walls yourself?

If there is a problem - a crack in the wall of a panel house, and there is no idea what to do, first you should decide on its type. If the size of the crack is insignificant, the easiest way is to eliminate it with foam, followed by plaster and putty. But you should not fill large cracks with construction foam or other components, as this will accelerate crushing.

Through cracks are the most dangerous and their rather sensitive expansion will lead to the fall of the floor slabs. This solution can only be a temporary solution to survive the winter, during which it is irrational to do major repairs.

In addition, professionals in many cases recommend using gypsum mixtures; they are easy to find these days. The repair technology is quite simple. The crack “opens up”, is cleared of dust and dirt, the surface is washed with water and dries.

After reading the instructions, mix it with water, stir until smooth without any clots and seal the crack.

Apply the solution using a spatula. Do not forget that gypsum tends to expand, so you need to make sure that there is a sufficient amount of solution in the cracks. If you do not take this point into account, there will be more gypsum than necessary, the crack will worsen, and a new displacement of the wall will arise.

Once the removal is complete, you need to let the plaster dry completely, this is about 5-6 hours. Then use sandpaper to clean off any remaining plaster. And admire the updated smooth wall.

You can also make a good old 3 to 1 mortar, parts sand to parts cement, adding water. This solution will be most suitable for uniformity to the panel wall. It is applied in the same way as gypsum mortar, using a spatula. When dry, it has less impact on the wall, but here you need to understand a little about the properties of sand, it should not be greasy.

It is also recommended to apply a mesh on the outer surfaces of the crack; it will stop the appearance of small cracks when the solution dries. It will create a so-called skeleton for structural strength.

To stop the development of large cracks, you can install a channel (anchor) or metal plates. To do this, the wall is cleared of plaster, approximately 50 cm in each direction from the edge of the crack, and plates are installed. They are fastened with dowels or long bolts, and for the second option it is better to drill through the wall. First, everything should be prepared, cleaned and blown with foam, and then insert the anchors into the prepared place and secure with the specified fasteners. Now there is enough information about what to do when a crack is detected in the walls of a panel house to resolve the issue.

Who should pay for cracks in the walls of a panel house?

Responsibility of the management company regarding cracks in panel houses

First, you need to decide on the situation and find the real root cause. These may be the builders themselves, also developers, neighbors or third parties. To do this, you need to contact a management company or homeowners association, which first draws up a deed, installs beacons and monitors their position. And then follow the procedure described earlier. If the situation is complicated, with a fairly large crack, when the management company and the HOA do not take any action, it is worth filing an application with the City Housing Inspectorate and waiting for the commission to appear.

But it is worth remembering that since 2010, the Supreme Arbitration Court of the Russian Federation has issued a resolution, the essence of which is that this issue is completely assigned to the management company. And then she deals with the search for the root cause and the culprits, if any. The commission, which must include an engineer from the BTI, must reflect in the act everything that is said regarding the cracks in question, objectively. It is also advisable to have neighbors as witnesses. Then the housing office must do something concrete. They should have a specific deadline of 2-4 weeks to make a decision, and after this period, they can prepare a letter to the local administration. Then ask the administration for an independent construction assessment. Here you need to be persistent and not let go of the situation.

Remember what they will tell you: cracking in panel houses is a common occurrence, and you don’t have to do anything. So globally, there is no reason to worry.

Instead of letting the situation go, this is: first a complaint is written, a week or two later a call is made to clarify the current state of affairs. When the period for consideration of a complaint by law expires, immediately file a complaint above. And then things will really get going. It is also good if there is an open website for complaints to the regional or territorial administration (addressed to the governor).

Cracks in the walls of the house, how to avoid it:

Noticed a mistake? Select it and press Ctrl+Enter to let us know.

Comments

A Svarog specialist will look at your question, and if something can be done, he will give his recommendations. Today or tomorrow he will comment.

Thank you very much! Will wait.

It’s difficult to tell you something based on 1 node.. The fact is that even if you knock out 1 of the panels in a panel house, the building should stand as if nothing had happened.. It’s clear that your plate joints have been made incorrectly, this is a reason to start lifting noise.. The fact that you have voids in the slab, you need to look at the layout of the house, perhaps some other panel could fit here.. The ceiling can rest on 3 sides (although this is also wrong). It’s not that I’m saying that everything is fine with you, you just need to look at the whole apartment and do an examination.

I would advise you to first invite a commission from the housing office to record everything that you consider necessary. Before doing this, tap all the walls (for voids), look for places that you don’t like (you think something is wrong). It doesn’t matter whether it’s correct or not, indicate everything in the act. Make a copy of the BTI plan and mark all problem nodes. Make sure that the BTI commission (there should be an engineer from the BTI and, as a rule, someone from the authorities) notes everything that YOU say, and not just what they need. Invite neighbors to the inspection (as witnesses). Next, the Housing Office must do something (caulking the seams is garbage, don’t even listen to them). Give them a deadline to make a decision (2-4 weeks), otherwise they won’t bother, tell them that after this period you will prepare a letter to the local administration. Then pester the administration until it makes an independent construction assessment. The main thing here is to be persistent and continually put pressure on the local authorities. And this is done like this: first write a complaint, a week or two passes - call and ask how things are going there. As soon as the period for consideration by law ends, immediately file a complaint above, etc. You won’t believe how things will turn out there, especially if there is an open website for complaints, like we have in our region (addressed to the governor). The main thing here is not to sit idly by; if the house is really in disrepair, then first of all you need to prevent it from collapsing.

Cracking in walls and its causes. A case from our practice

Some problems that are associated with the reliability of certain buildings sometimes cause panic attacks in people. Such situations happen quite often, and one of them was voiced by the owner of an apartment in an old 9-story panel building:

We live on the 5th floor and both of our 2 rooms share an external wall. It is she who causes us great fear. We regularly hear clicks and crackling sounds, and this is especially noticeable at night. This situation has been going on for several months now, and now the appearance of strange sounds has become more frequent (it’s summer). There are no visible cracks in the wall. We are wondering whether it is worth continuing to live in our apartment or whether it is time to change our location before it is too late.

Drawing up an application to the management company

Many people are interested in filing an application with the Criminal Code. There is no standard sample documentation, but there is certain information that must be in the application:

- the initials of the company director are indicated;

- personal information of the client, methods of communication with him (phone number, mail);

- if there are any errors, the application may be rejected;

- the essence of the application, the problem that arose. Complaints that indicate violations of regulations and laws are approved.

What else is stated in the document:

- information about the company, its location and information about the director;

- information about the client, name, contact information, place of residence, title of the document being submitted (complaint, application);

- the situation due to which the statement is being written;

- a request to resolve the problem, what solutions the client expects from the company;

- date of application, signature;

- It's better to attach real evidence. Attach a photo of the cracks in the wall;

- indicate the required dates, personal information, contacts and signature.

There are two ways to submit an application:

- make several analogues of the documentation . Take one to the Criminal Code. The secretary must take the document and identify the entry with the date of consideration of the application. In case of refusal, it is worth saving time and moving on to another method;

- find all bills for the last month. They have the company's mailing address. You can send your application by email.

This is all the basic information you will need.

How to understand the reasons for the formation of cracks on the walls of houses

Be sure to record the temperature and amount of precipitation during this period. It is advisable to keep this record for a whole year.

- Fashion house with tools

- Rolled metal. Sheets

- Larch windows

To clearly see what changes are taking place, you need to attach alabaster lumps to the crack, after soaking them. They will resemble plasticine in consistency. Beacons must be installed at intervals of 1 meter throughout the crack. Well, by checking such marks at a certain interval, you will determine the reason:

- Naturally, if the mark cracks, or maybe even falls off, the crack will grow. Based on the gap, you can draw conclusions about how quickly the cracks increase.

- The mark may crack, but there will be no gap left, dynamic loads are applied to the wall, and there are no stresses or further discrepancies in the material.

- The mark is intact and there is no tension in the wall. This means that the crack appeared as a result of the shrinkage occurring once.

At the same time, it can be quite difficult to determine the causes of cracks on your own. Therefore, in many cases it is still worth turning to professional craftsmen. After all, the matter is quite serious.

Checking the apartment

What should be in the apartment is written in the DDU. Look for the item “Characteristics of the object” in your contract - usually at the very beginning, in the section “Subject of the contract”.

1.3. The apartment is transferred to the Shared Construction Participant with partial finishing and the following types of finishing work: finishing the walls with plaster; floor covering - cement screed; installation of plastic windows and balcony doors; glazing of the loggia; installation of a metal inter-apartment (entrance) door. Installation of an electric stove, as well as horizontal wiring of the water supply system are not included in the price of the contract and are carried out by the Participant in shared construction independently and at his own expense.

If you have something in the DDU, but in fact it is not, write everything down in the defect report.

The first leaders of Moscow are big people. They treat with contempt the cheap low-rise construction proposed by deputy Alexander Lebedev, believing that the panacea for solving the problems of affordable housing is the construction of concrete high-rise buildings. As Moscow Mayor Yuri Luzhkov stated in one of his recent interviews, the modern urban development trend is super-tall buildings made of glass and concrete. The mayor ignored the well-known fact that up to 70% of the population of developed countries live in low-rise cottages. Following the tastes of the mayor, in Moscow they build and sell at exorbitant prices outdated boxes made of concrete lined with marble for the rich, and concrete decorated with cheap brick-like tiles or simply painted for the common people. However, it turns out that this housing may be downright dangerous.

Causes of wall cracking

Before repairing a crack in the wall, it is necessary to find out the destructive factors that served as the basis for the occurrence of this undesirable phenomenon. One of the options for classifying cracks according to the main possible causes of the process is given in the table below.

| № | Types of cracks | Possible causes |

| 1 | temperature | arise due to periodic or sudden fluctuations, or because the foundation freezes |

| 2 | deformation | non-compliance of existing loads with design loads |

| 3 | constructive | the use of low-quality solutions or grades of material that do not correspond to existing loads during the construction of a structure |

| 4 | shrinkage | are formed as a result of construction work near the building associated with digging pits and trenches |

Plasterboard partitions become deformed when in direct contact with water or when used in wet areas.

The nature of the location on the walls of the house and the parameters of the cracks indicate the reasons for their formation. Their direction is influenced by acting loads, for example:

- the presence and location of numerous cracks in the wall of the house on their surface indicates wear and tear of the materials;

- cracks widened at the top are evidence of foundation subsidence, and cracks thickened towards the bottom are evidence of the action of significant vertical loads.

Based on depth and direction, defects are divided into:

- inclined;

- horizontal and vertical;

- straight and curved;

- surface and through;

- closed.

Vertical fault

Based on the size of the cracks, the following types are distinguished:

- small – up to 5 mm;

- medium – 5-10 mm;

- wide – more than 1 cm.

Repairing cracks, both internal and external, should begin with identifying the cause. An analysis of their appearance will help with this.

Features of shrinkage in different types of houses

House shrinkage is a change in the geometric parameters of building elements due to the drying of the materials from which they were made. This process must be taken into account when constructing a structure, since it is natural and impossible to do without it. With proper calculations, shrinkage will occur harmoniously and without consequences for the structure.

Settlement of the building, with which shrinkage is sometimes confused, is, on the contrary, not natural and signals instability of the soil in the selected area or weakness of the foundation. Settlement can cause not only cracking of walls, but even their collapse.

The degree of shrinkage of a building directly depends on the material chosen for construction. Wooden buildings are considered the most problematic in terms of shrinkage. Concrete, foam blocks and brick are also susceptible to this process, but not in such a pronounced form.

Panel

Shrinkage of a panel house occurs on average per year. The changes occur so noticeably that the rough coating will in no way be able to hide traces of deformation. For the first renovation, it is recommended to use coatings that can then be easily dismantled - laminate or linoleum. The main part of the shrinkage can be quite noticeable in relation to changes in the geometry of the planes of the walls, floor and ceiling. The result may be noticeable cracks and distortions in the area of corners and tile joints. The slabs themselves remain unharmed. Very often, after shrinkage, apartment owners have to think about the need to level the floor. Ideally, of course, it is better to wait with repairs until the active stage of shrinkage has passed. It may not be so comfortable, but the financial losses will be minimal.

Brick

In the production of building materials, technology includes so-called shrinkage protection. Therefore, if shrinkage has a significant percentage, this indicates low quality of the material, or that the builders violated standards during the construction of the building.

At the production stage, the brick undergoes a drying procedure, due to which the percentage of moisture in the product is reduced to zero. This means that further evaporation, which could lead to shrinkage of the material, is eliminated. Concrete does not hold water in itself. In this case, the cause of shrinkage may be freezing during the cold season or improper load distribution within the structure. If the building was erected in the autumn-winter period, there is a high probability that the materials may get wet, and when saturated with moisture, freeze. As a result, inside the cracks and pores, the moisture turns into ice, which tends to expand. This can lead to severe external cracks.

Another disadvantage of brick buildings is the large number of seams. These gaps, if the masonry was not of sufficient quality, can accumulate moisture inside them, which will expand or contract under the influence of temperature changes. The porosity of brick, in comparison with other types of building materials, is its advantage and disadvantage at the same time. When building brick houses, builders must be very careful to ensure that all gaps are minimal and well-designed. The degree of shrinkage of a brick house compared to a wooden one is minimal, but it will take 3-4 years.

A crack in the ceiling is the first sign of building shrinkage

Monolithic frame

The basis of a monolithic frame structure is a load-bearing frame, made not using welding, but made using vertical columns. This is a solid system in which the frame plays the role of support for the structure as a whole. With this approach to construction, the risk of cracks is minimized.

Shrinkage in monolithic houses is minimal compared to other types of buildings, since the solid structure qualitatively distributes the load on the foundation, due to which shrinkage occurs evenly. For people living in the house, the changes are almost invisible compared to a brick building. However, there may be subsidence of soil under the monolith. In this case, a strong frame protects the building from significant deformations. This makes it possible to carry out repair work in a new building almost immediately.

True, if sufficient geological and geodetic research was not carried out or there were serious violations in construction technology, then even a monolithic structure can exhibit unusual miracles of shrinkage.

DIY repair

Often during repair work you have to deal with unpleasant defects. They are discovered while re-sticking wallpaper or leveling a wall for painting. You can deal with minor flaws yourself. When there are more defects outside than inside the house, it makes the job more difficult. Of course, it is difficult to deal with the cause, but you can try to hide this defect.

Puttying cracks in a monolithic house

To “cure” defects in monolithic walls, you will need the appropriate tools and materials:

- sealing composition (sealant, foam) and concrete mortar;

- putty knife;

- sanding mesh and holder for it;

- brush with stiff bristles;

- jointing tool.

First you need to widen the flaw by beating the edges with a hammer for better adhesion of the crack to the putty. Clean the defect from dust and pour sealant into it, then level the seam with concrete mortar. What to cover with? You can, of course, use only the solution, but the sealing compound will not allow it to appear anymore. After drying, you need to sand any unevenness well.

What is the best way to cover up cracks in a load-bearing block wall?

Smooth cracks appear on the masonry when it is not reinforced. There are several putty options for wall repair. Let's look at some ways to eliminate the defect.

- clean and, if necessary, expand the crack;

- clean from dust;

- using metal E-shaped anchors secured with dowels, strengthen the crack between the blocks;

- add pieces of broken cinder block to the solution (the smaller the better) and plaster the defect.

- widen the crack;

- prime;

- seal with mortar.

For small cracks, it is permissible to use tile adhesive, mounting foam or special foam for blocks.

If there is a straight crack in the corners, how to fix it correctly

A straight corner crack must first be opened, primed with a tenacious “Soil-Contact” primer and the seam sealed. To do this, take the Isogypsum putty on a spatula and rub it well into the flaw. Place a mesh on top of the putty. After drying, smooth out all uneven surfaces.

How to insulate walls, floors, ceilings, and how much it costs

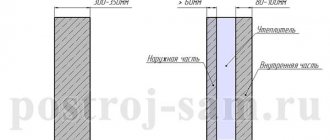

There are frameless and frame sound insulation. Frameless ones are assembled from multilayer panels. They are mounted directly to the wall using fasteners that do not conduct sound. In frame systems, the insulating material is fixed using a structure made of metal profiles. Essentially, this is a modification of plasterboard walls that are installed to, for example, divide a room into two.

When choosing, keep in mind that insulation differs not only in design. The frameless system is three centimeters thinner than the frame system, and it is no less effective. If you want to lose less space, choose panels. But there are limitations. Firstly, they are mounted on walls with a thickness of at least 80 cm. Secondly, objects weighing more than 35 kg cannot be attached to a linear meter of panels. Installing air conditioning, cabinets or shelves will not be a problem.

But if you plan to mount something heavier on the wall, then it is better to choose frame sound insulation; depending on the design, it can withstand from 70 to 150 kg per linear meter. It is also easier to route wires in it, since you don’t have to hide them in the wall. It is enough to place the cables in a polymer corrugation and lay them behind sound insulation.

The most reliable materials for soundproofing are: mineral and stone wool, plasterboard with acoustic properties and acoustic panels.

Chat rooms and forums are full of stories about how thin roll insulation, such as cork or vinyl, saved you from noise from a neighboring apartment. Don't believe it. Sound waves are well damped only by massive materials that can simultaneously absorb and reflect them. Lightweight thin structures are almost useless.

Frame wall insulation

Frameless wall insulation

Soundproofing walls

Frame method. A frame of metal profiles is erected at a short distance from the wall; slabs of sound-insulating material, such as mineral wool, are inserted into the space between them. Then drywall is attached to the profiles. The seams between the sheets and along the perimeter of the insulation are treated with vibration-isolating sealant. Ready. You can wallpaper or paint.

Frameless method. Soundproofing panels are fixed to the walls with special fasteners and do not require the installation of a frame. Fasteners can be of different designs. The ones you need are included, so you don't have to look for them.

The places where the ends of the panels come into contact with adjacent surfaces - the floor, ceiling and walls - must be taped twice with vibration-isolating tape and sealed with vibration-acoustic sealant. It also processes all the seams between the panels.

If you are renovating a secondary home, frame sound insulation is more appropriate. Since you don’t need to ditch the wall to make electrical wiring. The wires can be routed inside the structure, in a corrugated structure. Plus the wall is immediately flat, which is very convenient when finishing. And of course, you get good protection from external noise.

Technical Director

Here and below, the cost of sound insulation is calculated based on data from the portals profi.ru, youdo.com (work of private craftsmen) and specialized companies Tiho74, Besshumov.ru, Maxforte

Soundproof the wall yourself, cost 1 m²

Soundproofing a wall by a private master*, cost 1 m²

Turnkey wall soundproofing** in a specialized company, cost 1 m²

* You buy the materials yourself, but the master can help with the choice.

** Companies purchase materials themselves.

One ZIPS panel measuring 1.2x0.6 m weighs about 20 kg, the additional load on the wall is up to half a ton. To securely fix such panels, you need to deepen the screws into the wall by 60 mm. Therefore, it is not recommended to install the system on walls thinner than 80 mm. If the partition is thin or cannot withstand heavy loads, you will have to choose a frame method of sound insulation.

ZIPS - soundproofing panel system

Frame ceiling insulation

Frameless ceiling insulation

Ceiling soundproofing

Frame method. A frame made of metal guides is attached to the ceiling using vibration suspensions. The space between the guides and the ceiling is filled with mineral wool slabs. Acoustic plasterboard sheets are mounted from below to the frame. Along the perimeter, the ceiling is separated from the wall by vibration-isolating tape. The seams between sheets of drywall, as well as along the perimeter of the insulation, are treated with vibroacoustic sealant.

Frameless method. Frameless structures for ceiling insulation are assembled mainly from soundproofing panels. They are attached to the ceiling through vibration units (the places where fasteners should be placed are marked on the surface of the panel), and are hemmed underneath with acoustic plasterboard sheets. The joints with the wall are treated with sealant. A finishing layer of drywall is attached over the panels, which is usually painted.

Soundproof the ceiling yourself, cost 1 m²

Varieties

There are two types of cracks in the walls of panel buildings: open and closed. The names explain the problem. Closed defects appear inside the walls and are not visible without special equipment, but open ones can be noticed at any time.

Any of these types of cracks are essentially developmental and without repair will only lead to deterioration.

You should also be careful about where a crack appears in an outer or inner wall, in a load-bearing wall or in a partition, perhaps on the ceiling or somewhere else. To independently check the risk of a split, you just need to install a plaster beacon.

If the beacon remains intact during the season, it means that the defect has not developed and can be eliminated. At the same time, the growing cracks will show their changes and will constantly grow. Stable defects are the best when considering a problem like this.

In addition, there are technological defects that arise during drying of components used in finishing and construction.

ATTENTION! To avoid this problem, they usually use different fastening materials that are similar to meshes.

These cracks will not lead to the destruction of the house, but will only change the external characteristics. If you work hard and distribute the defects in the walls into groups, you will get the following:

- For reasons: additive, deformation, temperature, design problems, and also wear and weathering.

- By destruction: shears, pressure and ruptures.

- In direction: oblique, vertical and horizontal direction.

- Shape: different contours.

- By depth: external and through cracks.

- By risk level: safe and dangerous defects.

- By time interval: stable and unstable-permanent defects.

- By disclosure: large, small, hairy, passing near the plaster, developed. To determine the causes of horizontal defects, it is worth calling an expert.

Characteristics and types

Two types of cracks may appear in the load-bearing structures of an apartment building: open and closed. The first ones are visible to the naked eye, the second ones are visible using special equipment. Any crack can be characterized:

- By type of destruction: ruptures, cuts, crushing.

- By depth: through and external.

- Direction: vertical, horizontal and inclined.

- By time: stable-constant and unstable-constant.

- For reasons: deformation, structural, temperature, external (wind), resulting from wear.

- By opening: small, large, developed, hairy.

What do we offer

Our company can offer ]sealing of walls[/anchor] for high-rise work. Teams of our industrial climbers work in Moscow and the Moscow region. Frequently asked questions about sealing seams: / The management company does not fulfill its obligations, where can I turn? / Practice of filing an application to the Court for sealing seams / Sample application to the Management Company for repair of interpanel seams / Secrets of correctly writing an application for interpanel seams in the Criminal Code / Who should repair a balcony in a privatized apartment? / List of basic works for routine repairs and operation of buildings and structures / Seams in a panel house are leaking, sample application / How to force the management company to seal interpanel seams? / Who should repair the interpanel seams in the house? / Seams in a panel house are leaking, sample application / Time frame for major repairs of interpanel seams

What organizations do repairs?

To carry out high-quality repairs to the facade of a panel house, it is better to seek the help of specialists. Many companies provide such services, but not all of them use high-quality materials and involve professionals in carrying out the work.

always works for results, performing repairs in good faith, in compliance with all existing norms and standards. Services provided by our organization:

- Façade inspection.

- Insulation and sealing of interpanel seams.

- Carrying out a number of façade repair works . We carry out the full range of work, from professional crack sealing to subsequent cosmetic finishing.

When contacting Stroy MD, you can always count on selecting the most optimal option for resolving the problem and the highest quality of work performed, ensured by the use of modern equipment, high-quality construction and repair materials, as well as the involvement of experienced specialists with knowledge of all technological features and the presence of the necessary approvals.

How to seal a gap

In construction practice, cement, rubber, polyurethane foam, sealant, and various types of mastics are used to seal cracks. Their goal is to evenly fill the space and prevent the penetration of moisture and wind into the rupture areas.

If damage to the load-bearing structures of an apartment building does not require major repairs, everyone has the opportunity to repair the damage using a grinder, chisel, hammer, spatula, sealant, masking tape and putty. To seal gaps in panel houses, you need to perform the following steps:

- Drill a hole along the edges of the crack (so that the source of destruction does not increase over time). When performing this operation, the fittings may be damaged. Vulnerabilities should be identified in advance.

- Using a chisel or grinder, create a 10 mm chamfer (beveled corners).

- Remove dust using a vacuum cleaner or broom.

- Treat the surface with a primer.

- After the primer has dried, you can stick on the paint mesh and apply putty. If the wall is cracked to a significant extent, you will need to fill the void with cement mortar.

- Re-prime the restored area. If the gap reappears, it is best to contact a specialist.

Brickwork

Many modern panel houses have brick walls. Possible reasons why walls crack in brickwork are drying out seams, lack of ligation between bricks, etc.

In this case, they resort not only to restoring the damage, but also to strengthening it (with the help of metal plates). Stages of work:

- Clean the surface from dust, brick chips, damaged mortar and prime the surface.

- Sew up the areas with metal plates (perpendicular to the seam).

- Pour the solution into the resulting gap. In places where it does not exceed 5 mm, it is more advisable to fill it with a special sealant using a gun.

- To ensure a uniform surface and color, it is recommended to apply tile adhesive. In addition, the glue has excellent frost and temperature resistant properties. The final operation will be grouting the seam and leveling the surface using putty.

Cosmetic repair of cracks on walls

If the glass beacon shows that the crack is no longer spreading, there is no need for such complex repairs. It is enough to simply make a cosmetic one.

To do this, the crack must be processed, removing all the pieces that do not hold well, and filling it, as described above. When the hole is closed, the surface is plastered and puttied. In this case, it is recommended to use construction mesh for plaster.

The mesh needs to be glued onto the crack so that its edges extend ten centimeters beyond the sides of the crack, and only then plaster this place. The mesh will create additional reinforcement and prevent the appearance of new microcracks from shrinkage of the material.

Also, when renovating a house, you sometimes have to deal with microcracks that appear on normal and well-reinforced walls due to thermal expansion. This usually happens due to the fact that no reinforcing mesh was used when putting them. It is best to completely re-plaster such walls and reinforce them with mesh. This will guarantee that microcracks will not appear in the future. But if this is not possible at the moment, elastic putty mixtures can be used to repair such defects.

Do not try to fill large cracks with polyurethane foam or other materials, as this will accelerate its expansion. Through cracks are the most dangerous and their strong divergence leads to the collapse of floor slabs. This method can only be used temporarily to survive the cold season, during which major repairs are difficult to make.

We remove cracks in the house that can destroy it

You can strengthen the foundation in different ways, but the most reliable way is to make it solid again using proper reinforcement and increasing the area of support on the ground. To achieve this, you need to dig a trench close to the foundation, about one and a half meters long and 40–50 cm wide. The depth should be about 40 cm below the foundation, but not less than to the freezing point.

Then we remove the soil from under the foundation to the level of the bottom of the trench. This will allow the concrete to flow under the old foundation and almost double its area, while reducing the load on the ground by the same amount.

We reinforce this space with reinforcement rods no less than 14 mm thick, laying them horizontally along the foundation and sticking the ends into both sides of the trench at least 20 cm. There should be six or more such rods. Two rods at the very bottom, two in the middle and two at the top. This arrangement of reinforcement in the foundation makes it work not by bending, but by breaking, which is ten times more effective.

We drill holes in the foundation to drive pieces of reinforcement into them and weld them with the previously laid rods. Then we fill this trench with concrete, making sure that the solution well fills the void under the foundation. Ideally, it is recommended to use a vibrator for this, but if this is not possible, you should vibrate the concrete well manually using a long rod.

Several such trenches need to be made under the wall, the number is determined by the distance. The gap between the trenches should be about two meters. After the concrete has set (two weeks are usually enough for this), you can start digging the same trenches between the resulting new foundation blocks.

By digging out the following trenches, you will free the ends of the reinforcement rods (which were previously driven 20 cm into the ground) and will be able to connect individual blocks of the new foundation together into a single reinforcement belt using welding and two-meter pieces of rods.

After filling all the trenches with concrete, you will get a strong new foundation with an increased area of support on the ground and tightly connected to the old foundation. Now you can safely begin to repair the crack itself, since the new reinforced foundation will not allow the wall to diverge anymore.

To repair a crack, first of all you need to clean its edges from those parts of the wall and plaster that are barely holding on. Then it needs to be filled with some kind of solution, the choice of which depends on the width of the crack and the building material from which the wall is made.

If the size of the crack is insignificant, the easiest way is to fill it with polyurethane foam, followed by plaster and putty. When the crack is large, the hole is filled with the material from which the damaged wall is made, followed by further finishing.

The most difficult repair is a crack on a wall that is made of finishing bricks. Before laying, broken bricks are knocked out, and new ones are put in their place, matching the pattern of the masonry.