You often have to face questions: which hot water supply system - open or closed - is better, what are the differences between them, what to choose for a private home, etc. It is important to understand that the concept of "open" and "closed" (sometimes called "loop" ") does not refer to DHW systems, but to heat supply systems (HS), of which the DHW system is an integral part. Depending on how the hot water supply is organized in the heating supply system of the facility, this system is classified as either open or closed type.

Dependence of the system on the heat source

If we consider hot water supply schemes on a large scale, they can be divided into two groups:

- Centralized , when water heating is provided by boiler houses or thermal power plants.

- Local , which serve only one object.

In centralized systems, briefly called TsSGV, both closed and open hot water supply systems can be used. To provide warm water to the civilian population and organizations, the same water is used as a coolant, only highly overheated.

The district boiler house heats the water

In industrial enterprises, waste (secondary) steam is often used as a coolant. But we won’t delve into these jungles - let’s talk about the most common option.

The difference between the two schemes and their applicability

So, let's figure out what an open and closed water supply system is.

- In open, or as they are also called, dead-end schemes, during the water treatment process, boiling water is diluted to the required temperature with cold water and served to the consumer. That is, the water that needs to be heated is in direct contact with the coolant.

- This does not happen in closed circuits - in them heating occurs due to heat exchange. This is the main difference between an open and closed hot water supply system.

Please note: It is easier to obtain hot water using the open method, but at the same time it loses quality and cools down faster. To maintain a high temperature longer, the system must be looped. It is the circular circulation of water that is the distinctive feature of closed circuits.

Open (dead-end)

A dead-end network is a very convenient option for buildings with a small number of floors and short risers. They are often designed for domestic (non-industrial) water supply systems of industrial enterprises and for any buildings with stable or long-term consumption of hot water (residential buildings, catering establishments, baths and health institutions).

In the photo - a dead-end (open) network

- In terms of metal consumption, an open scheme is more profitable. However, due to rapid cooling, in order to wait for hot water in the tap, you have to drain the cooled water - and this is already an irrational use of water resources. Therefore, in high-rise buildings this scheme is not used at all.

- In terms of maximum heat transfer, which determines the efficiency of the system as a whole, open and closed hot water supply systems are approximately the same. Their performance will differ only if one of these systems has a heat pump, which significantly increases the efficiency.

Open and closed water supply schemes provide water of different quality

Note: Both schemes have advantages, but they are different. In particular, the open one has a lower price. It is also important that in these systems the water most often corresponds to drinking quality - but for this it must be constantly deaerated.

Open circuit structure

This is roughly how a dead-end circuit works

This system is the simplest.

- If we talk on the scale of a private home, then it contains a device that heats the water, a pipeline through which it moves to the distribution points, and a circulation pump, which, in fact, ensures transportation.

- If we talk about installation options, then there are schemes with upper and lower wiring. The first can only be implemented in buildings where it is possible to install water heating tanks on the under-roof technical floors.

- With lower wiring, all equipment is installed in the basement, where it is much easier to maintain it. However, the pressure in such a system is practically never the same for all floors, so to maintain it, booster pumps are installed in houses with lower distribution.

There are three factors that influence the speed of water movement.

- Dynamic pressure;

- The height to which water is pumped;

- Inevitable losses.

Therefore, float sensors are installed in the tanks from which water enters the pipeline, and pressure switches are installed on the pipes themselves. And so that in order to carry out repairs it is not necessary to drain water from the entire system, all pipeline branches are equipped with shut-off valves, which make it possible to temporarily cut off a section from the system.

Operating principle, pros and cons

In general, the system looks like this: two pipes - supply and return - are connected in an elevator unit or heating point, where the water is brought to the required 60 degrees Celsius. Then hot water is supplied to the internal pipeline of the building, to dismountable points.

Entry of supply and return pipes into the building

- The stability of the pressure in such a network is maintained hydraulically, when cooling water is squeezed out by hotter water. At the same time, thermal energy is transferred to the maximum, without requiring high coolant costs.

- A minimum of equipment in the system facilitates its operation, and, accordingly, makes the scheme the most economical. But all the benefits from the design are “eaten up” by the costs of water purification.

- The main disadvantage of a dead-end circuit is the fact that when there is no stable supply of hot water, it quickly cools down. Many people know firsthand how long it takes to turn on the tap early in the morning for hot water to come out. It turns out that residents who have water meters simply pour their money down the drain.

You have to wait a long time before hot water comes out

- Due to the rapidly cooling water, the temperature in the heating radiators is also not very stable. Another significant drawback is the inability to heat bathrooms, since heated towel rails only heat up when the hot water supply is open.

- However, most older residential buildings receive water according to this scheme. This means that water is actually taken from the heating system - which is why it is, in fact, called open.

Note: In new buildings, a newer, closed scheme has long been used, which contains special equipment that heats the water. And according to Federal Law 190, from January 2022, the extraction of coolant from heating systems will be prohibited, and all capital construction projects will switch to closed schemes.

How does a closed system work?

Closed (ring) network

We have figured out one heat supply scheme, now let’s consider the second option - after all, closed and open water supply systems function completely differently. In a closed network, in contrast to a dead-end circuit, water for the plumbing is not mixed with the coolant, but is heated from water from the heating network. That is, heat exchange occurs.

The heat exchanger is an integral part of the loop network

Open circuits have significant drawbacks, as described in the instructions in the previous chapter. But since they want to abolish dead-end systems at the legislative level in favor of ring (closed) systems, it means that the latter have undeniable advantages over the former. What are they?

- Stable quality of heated water;

- Constant temperature, for which the minimum is +70 degrees;

- Sanitary and other control of systems is carried out more simply.

Disadvantages of a loop network

As usual, positive characteristics entail an increase in the cost of the system, which is a significant disadvantage of closed circuits. They become more technically complex, and the price increases due to the introduction of individual water heaters with a corresponding arsenal of communications.

Note: When connecting such a system to the heating network, you also have to use brass tubes, which are also not cheap. The thing is that polymer tubes cannot withstand intense heat. Ferrous metal is highly susceptible to corrosion due to increased oxygen release. Brass in this regard is more stable, and allowing you to do without expansion joints on the body, it simplifies the design of the tube sheets.

The disadvantages of a looped network include the difficulty of regulating water flow. A storage tank must be installed near each boiler, which is not always technically possible.

Next to the boiler, a self-assembled hydraulic accumulator

Even with proper operation, heating networks operating in a closed circuit suffer water losses and have to be regularly recharged using a booster pump. Normally, these losses account for 0.5% of the total volume of water in the network. Its quality is ensured by vacuum deaerators installed in the central heating substation.

All this equipment operates from the mains, which means that electricity costs also increase, which also cannot be considered an advantage.

Housing and communal services in Russia

Hot water supply systems (DHW) based on their operating principle are divided into open and closed.

An open DHW system is a system in which water for hot water supply is taken directly from the supply and return pipelines of the heating network (heating system), mixed in special devices - hydraulic elevators and supplied to water taps. A closed DHW system is a system in which it is taken from the water supply network cold water is heated by the heat of network water in special heaters - boilers located in heating points (in basements) of houses, without coming into contact or mixing with the coolant - the water of the heating system, and then goes to the water taps of the MKD DHW system.

There are independent open hot water systems in which there are no connections between hot water and heating pipelines, and cold water for hot water needs, taken from the water supply network, is heated at thermal power plants, in district or house (roof) boiler houses and supplied to the apartment building through separate hot water supply networks .

The pressure (and, accordingly, flow) of water in hot water systems is created by pumps located at thermal power plants, in district or house (roof) boiler houses.

Most hot water supply systems, in accordance with regulatory documents, have a circulation system - pipelines and/or circulation pumps through which water continuously circulates. As a result, along the entire length of the hot water pipelines, including near water taps, the water temperature is constantly maintained in accordance with the requirements of the standards - not lower than 60 degrees C.

A hotline may not have a circulation line only if it is not designed by illiterate “specialists” or if thieving builders “forget” to build it with the connivance of their accomplices - city authorities, or if housing and communal services plumbers steal it for scrap metal.

However, in cases where hot water is constantly drawn from the DHW system (in bathhouses, in technological installations) and when the supply pipelines from the heat source to the water collection points are short, the DHW system may not have circulation.

Both open and closed hot water systems during design, installation and reconstruction must be equipped with devices for automatically maintaining the water temperature within standard values - not lower than 60 and not higher than 75 degrees. WITH.

(bases:

— clause 5.2.4 of the Code of Rules SP 30.13330.2012 “Internal water supply and sewerage of buildings” Updated version of SNiP 2.04.01-85; clause 15.14 of the Code of Rules SP 124.13330.2012″SNIP 41-02-2003. Heat networks" Updated version of SNiP 41-02-2003 (approved by order of the Ministry of Regional Development of the Russian Federation dated June 30, 2012 N 280); — clause 5.3.1 of the document “Rules and Standards for the Technical Operation of Housing Stock” (approved by the Post of the State Construction Committee of Russia dated September 27, 2003 N 170)).

The quality of water in open and closed hot water systems must comply with the requirements of SanPiN 2.1.4.1074-01 “Drinking water. Hygienic requirements for water quality of centralized drinking water supply systems. Quality control".

However, although the hot water of the DHW system should correspond in quality to the quality of cold drinking water, sanitary doctors do not recommend using it as drinking water, especially with an open DHW system, since in practice its contamination is not excluded. For example, at the beginning of the start-up period or after repair of hot water supply equipment, the water becomes contaminated with dirt and sediment washed out of the pipes. Therefore, it is recommended to use hot water mainly for laundry, washing dishes, and other sanitary and hygienic needs.

Classification of heat supply systems

In science, many options for systematizing communications are accepted depending on the parameter being studied. For us, first of all, it is important that there is an open and closed heat supply system. It can also be centralized (within a block, district, settlement or even an entire region) and decentralized (individual or local). Based on the quality of water supply, systems are divided into municipal and industrial. The total number of classifications is much wider, but they are not relevant to the topic under consideration.

Differences and similarities between the two systems

Many people are interested in the question: what is the difference between an open hot water supply system and a closed one?

In open or dead-end systems, before serving to the consumer, boiling water is diluted with cold water to the desired temperature. Heating water must be in contact with the coolant. In closed systems, heating is carried out due to heat exchange, which differs from an open circuit.

The easiest way to get hot water is by open method, but the water cools faster and loses quality. To maintain high temperature for a longer period, the circuit should be looped. A distinctive feature of closed systems is the circular circulation of water.

Both systems have advantages, for example, the open scheme has lower cost. Open and closed networks produce water of different qualities. To maintain drinking quality, water must be deaerated on a continuous basis.

Expert opinion

Ivan Bardov

The similarity of the two systems lies in the maximum heat transfer, which affects the efficiency of these networks. You can increase these indicators by installing a heat pump on any of the systems.

Features of an open system

It is characterized by the circulation of coolant obtained from common communications. An open hot water supply system is when water enters the batteries from the main hot water pipe. From the same source from which hot water goes to residents' taps.

The operation of the system is based on natural circulation. Due to physical phenomena, the cooling water, acquiring greater mass, will displace the hot flow, giving it acceleration. In some cases (in large systems), circulation is forced using pumps.

Open type heating is usually installed in high-rise buildings. The main advantage here is that there is no need for special mechanisms or devices for heating the coolant. For private households, such a system will be unnecessarily expensive, because the heating pipe will have to be connected to some high-rise building or a hole must be dug to connect it to the main line.

Main advantages

Let's list the main advantages:

- energy independence and centralized supply;

- smooth circulation of the carrier in the system without sudden pressure surges;

- ability to work in case of emergency due to redundant hot water mains.

However, an open heating system is not ideal.

Flaws

The main disadvantages include:

- high heat loss and, accordingly, unnecessary costs for heating water;

- dependence on the performance of large highways; in the event of an accident, the supply of hot water supply may stop in a large number of houses;

- water quality decreases due to defects in pipelines, in particular, rusty pipes;

- branched open systems require constant monitoring and careful calculations of supply volumes, heating temperatures and pressures.

Let's consider an alternative option.

Which option is better?

To understand which design of the heating system is better: open or closed, it is worth considering how they differ.

The main difference between a closed structure and an open one is the location of the expansion tank. In an open structure, it must be placed in the highest place of the house. But in a closed design, the tank can be installed anywhere, even on the same level as the boiler.

Insulation in a closed type of heat supply from the environment prevents air masses from getting inside. As a result, the service life of all equipment becomes significantly longer. Also, additional pressure is created in the uppermost components of the structure, which reduces the risk of air locks in the heating elements.

The open type of heating is distinguished by larger diameter pipes, which lead to additional inconvenience. In this case, the pipes have to be installed at a large angle to ensure circulation. Thick-walled pipes cannot always be hidden. In addition, in order to ensure correct hydraulics, it is necessary to take into account tilts, lifts, narrowings, turns, and connection options to radiators.

For a closed structure, pipes of a smaller circumference are needed. This makes the design cheaper

However, in such systems it is very important to ensure that the pump is installed correctly, otherwise it will become very noisy.

The closed type of heating, unlike the open one, is more durable and reliable. At the same time, it is able to maintain pressure at a constant level, and it is also possible to regulate it. The coolant in this design can be antifreeze rather than water. Simplicity of installation and quick start-up are also characteristic of a closed type of heating supply.

Among the advantages and differences, it is also worth noting the ability to connect additional equipment. Heating of this type is characterized by high efficiency, cost-effectiveness and the absence of the need for constant monitoring.

Of course, there are differences in the closed type, which cannot be classified as advantages. For example, the volume of the tank must be large and there must be an electrical network. Operation of a closed structure from other sources is possible, but only for a short time and in emergency cases.

The open design has a simpler installation scheme. It operates more silently than a closed one, and heats at a faster rate. You can fix faults in it very quickly, as well as turn it off completely. It does not need a power grid, nor does it need recharge in an emergency. Installation of the circuit does not require large expenses and a lot of time.

Air can get into the open type of heating, which causes various problems - for example, air congestion, rust. Unlike the closed type, such a system can boil or freeze.

The difference between the systems is quite significant. It is possible to say unequivocally which one is better only individually. To do this, it is worth once again emphasizing the main advantages and disadvantages of each system.

The closed design saves energy and supplies high-quality water, but the process of preparing this water itself is more complex and expensive.

The open design is very economical. However, due to long pipelines, the water there is of low quality. If you try to purify the water so that it has a better color and smell, then such a system will lose its dignity.

Closed hot water system

Requires your own heater in the apartment. A dead-end hot water system works on the principle of taking cold water from a common pipeline, which then passes through special equipment that performs heating. A closed hot water supply system is a more economical solution. The resident will be able to independently regulate the heating temperature.

What types of heaters are there?

There are two main options that are most common. Let's consider individual types of water heating equipment.

Flow devices

An example of this type is a regular geyser. The principle of operation is aimed at instantly heating the water passing through the water heater. The inconvenience of working with such a device is due to the fact that it must be turned on every time you need to use hot water. In this case, the crane should be running at this moment. Modern water heaters turn on automatically, but the gas wick must be constantly burning.

Heating devices

Storage tanks become a more economical solution. Such a device is larger than a speaker. It contains a container in which volumes of water are accumulated and gradually heated to the desired temperature. At the same time, heating in the tank is maintained with insignificant energy consumption. The disadvantage of the equipment is that it takes considerable time to achieve an acceptable temperature level. Boilers are usually powered by electricity.

Advantages and disadvantages

If we talk about the advantages and disadvantages of hot water supply, it is better to consider open and closed systems separately.

The advantages of an open system can be considered the following:

- it is easy to fill it and bleed air, which happens automatically through the expansion tank;

- It's quite easy to recharge. Since the pressure in the system does not require special attention, you can draw water without fear;

- the system functions well even in the presence of leaks, which is due to the high operating pressure in it.

The disadvantages include the following:

- constant monitoring of the water level in the tank;

- the need to replenish it.

The advantages of a closed hot water supply system include the following:

- savings associated with constant temperature;

- It is possible to install a heated towel rail.

A very important point in the hot water supply system is the presence of a hydraulic accumulator. It helps prevent some problems associated with pressure drops in the system. The hydraulic accumulator is a sealed tank containing a membrane partially filled with water. It divides the tank into water and air parts. If the volume of water in the hydraulic tank increases, then the volume of air correspondingly decreases.

If increased pressure parameters occur in the system, a signal is given and the pump is turned off. There is a pneumatic valve to regulate the pressure. Air is pumped through the nipple. Its quantity can be either added or reduced.

The hydraulic accumulator has the following advantages:

- preventing rapid pump wear. Since there is a supply of water in the tank, the pump will turn on less often, which contributes to its longer service life;

- stable air pressure in the system. The device helps to avoid sudden changes in pressure and temperature in the hot water supply system;

- resistance to water hammer. They practically do not occur and cannot harm the pump and the entire system;

- increased reserves of hot water. There is always a supply of it in the hydraulic accumulator tank, and it is constantly updated.

Calculation and recycling procedure

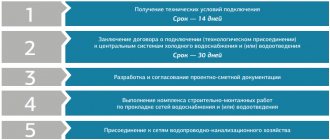

In order for the DHW system to be designed correctly, the following must be kept in mind.

- The drawing shows the circulation rings. They close at the thermal unit.

- There are 2 pipelines: supply and circulation.

- On the longest section of the hot water supply route, zones of maximum circulation heat consumption are noted.

- The diameter of the pipes cannot be less than 1.5 cm. Moreover, they must be 1-2 sizes larger than the diameter of those in the supply section. This is done to avoid air locks.

When calculating a heating installation, you need to keep in mind that an open system will be effective only at a short distance from the intake site and when the valve supplying boiling water is opened frequently. Otherwise, the consumer will receive cooled water.

Use of heating points

This is a separate room. It must contain thermal power plants connected to the heating network. Heat exchangers for hot water supply in an apartment building must have tools for regulating consumption, distributing hot water among apartments, and setting up the equipment itself.

An individual heating point in an apartment building is usually located in the basement. Previously, the system was installed in attics. In the event of a breakthrough, streams of boiling water spilled throughout the room and flooded the apartments. If an emergency occurred at night, it could lead to serious injuries or even casualties.

An alternative option is to build a heating station in a separate building next to the building. The purpose of the equipment is to convert the coolant, regulate the supply of hot water or heat, distribute the resource among apartments and turn off its supply.

Water heating equipment

A standard water heater can be used for domestic hot water or heating. In case of equipment breakdown, housing and communal services tariffs will not be reduced. Repair work will also fall on the shoulders of consumers, who are obliged to monitor its good condition.

Thermal energy component

It is responsible for heating cold water. Moreover, counters are not installed on the component. Before calculating the thermal energy for DHW, the following parameters must be taken into account:

- tariff for hot water supply;

- system operating costs;

- costs for coolant transfer;

- calculation of heat loss.

Also taken into account is the fee for regular water supply, calculated on the basis of consumption (RUB/cubic meter).

What is hot water recirculation (DHW) in a private home: diagrams and definitions

This is a supply line - a circuit piping - in which the coolant constantly moves through the system. It is needed to increase efficiency, and therefore the operating efficiency of boilers, which will result in an improvement in the level of consumer comfort.

Its arrangement solves several pressing problems at once. For example, when using it, the liquid does not have time to cool down, since it moves non-stop through pipelines - to the points of intake and back to the heating element (where it is heated) - which allows you to use it at any time, if the need arises, rather than waiting half an hour to take a bath .

In fact, the practical task of any implemented hot water supply scheme with water circulation in the system comes down to ensuring optimal thermal conditions. The temperature of the carrier suitable for operation is constantly maintained, due to which it enters a new cycle with minimal losses, especially since heat is transferred evenly at all stages of consumption.

The simplest wiring option is a ring with a pump that ensures continuous flow movement under pressure. Among its mandatory elements are tees responsible for the return of liquid and installed closer to the point of intake. The shorter the line, the shorter the heating wait time, but also the lower the overall performance.

Now let's turn our attention to solutions for different objects.

DHW circulation diagram in a private house

Here you need to pipe the heater in one or two circuits: most often it is played by a boiler, but a boiler, volatile or not, is also possible.

- The first must be permanently connected to the mains, but it is usually equipped with its own pump for pressurizing.

- The second does not require power from an outlet, but requires a timely supply of firewood or other fuel for combustion.

Using a boiler allows you to implement technically more complex solutions, for example, integrating bathroom and kitchen sink faucets, a heated towel rail and other elements into the line. Yes, as their number increases, energy consumption also increases, but overall savings also increase, which is especially noticeable with active fluid consumption.

Scheme of hot water supply (DHW) recirculation in a multi-storey building

In such cases, not direct, but indirect supply is relevant. The carrier is first heated, then sent to the pipes, passes through them, returns to the heating element, is again brought to the required temperature and goes to the next cycle. Each apartment (room) is a participant in the general wiring, which is characterized by the following features:

- The liquid moves from bottom to top or, much less often, vice versa, but always strictly vertically.

- Power is supplied exclusively from the DHW pipeline, and in the boiler itself, which is constantly running, the environment never cools down.

- The return of the flow is carried out through bends through which it flows back.

conclusions

The open hot water system is an obsolete scheme, which is being widely abandoned not only because of legal requirements, but also because of its key disadvantages, especially the low quality of water in the system. Closed CTs are installed in new buildings, private houses, industrial enterprises and production facilities. When using modern and energy-efficient thermal equipment, in particular plate heat exchangers, a closed-type system is the most economical, convenient and easy-to-use tool for creating an optimal indoor microclimate and providing consumers with hot water. You can purchase heat exchangers at the best price and order their installation services at: specialists will offer profitable solutions and provide after-sales service for the purchased equipment.

Advantages of a hot water supply system with circulation and its scope

The practical advantages are obvious:

- the stream is at least well warm immediately after opening the tap;

- It’s easy to adjust the temperature by turning the valve and adding a little cold water;

- there is no overspending - precious liters of liquid do not pour into the drain, because you do not wait for it to heat up;

- with constant use there are no traffic jams or clogging of pipes, and if they appear, they are immediately noticeable;

- a large number of end consumers are seamlessly integrated within one solution;

- it can be implemented on the basis of any heater - storage, indirect heating boiler or double-circuit boiler.

Hence the scope of application is clear. Such systems are relevant for one- and multi-story buildings, in which water treatment equipment is installed in a technical room, away from the inhabited rooms, and/or there are several bathrooms and many intake points. They are in demand at facilities with long communication lines and help reduce fluid losses and increase the efficiency of its heating and use.

Attention, this is a global solution, and therefore its implementation (regardless of the topology) is possible at the construction stage or at least a major renovation. It is futile to modernize an existing and standard plumbing complex - too much money will be required, it is cheaper and easier to implement everything from scratch.

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

Connection diagram for DHW recirculation: how to make it yourself

There are at least several popular strapping options that have emerged due to fundamental differences in the design, layout and configuration of houses.

Therefore, before starting work, it is necessary not only to select a specific solution (taking into account the type, volume and features of the heating element), but also to draw up a drawing with installation points for all elements - pump, consumption devices, etc.

In practice, there are 4 types of connections that are most in demand - we will consider each.

Through an indirect heating boiler

At its core, it is a reservoir with a coil connected to the boiler in such a way that the coolant moves in a closed circuit and in no case mixes with household liquid. For this purpose, it has five pipes:

- straight, from container to spiral;

- reverse, providing return movement;

- cold make-up;

- supplying the flow to the point of consumption;

- reverse, leading to the tank.

Attention, for successful circulation of hot water, the scheme also provides for installing the pump strictly on the return pipe. Such an engineering move will prevent overheating of the elements, and therefore helps maintain normal operation. It is important that all installed heated towel rails will be constantly hot, and this is the key to a healthy and comfortable microclimate in the bathroom, as well as the absence of mold and mildew.

Through a storage boiler

This is already a tank with thermally insulated walls, which receives the required volume of liquid from the boiler - 100-1000 liters, depending on the number of residents in the building and their needs.

Its contour is a loop, with a forward feed and a return line. The latter is connected to the make-up pipe, and so that its entry point is behind the shut-off valve assembly. It also houses a pump equipped with control devices.

This solution has two important features:

- The medium that is in the tank has one temperature, and the other that runs along the replenishment line has a second temperature, due to the cooled “return” and/or the effect of mixing layers.

- Heating is carried out solely by adding flow after spending part of the reserves.

When idle, the media cools down very quickly. Therefore, a hot water recirculation system with a storage tank is relevant only for those houses where water consumption is constant and quite high, that is, for multi-storey buildings, but not for country houses.

Using a double-circuit gas boiler

This option is usually chosen when there are a small number of end-use points and when only one type is intended to be used at a time, for example, exclusively washbasins. In such cases, a medium-power flow heater capable of providing up to 20 l/min is also quite suitable. It will turn out to be quite simple (and therefore reliable and durable) and economical.

To install it, you only need to organize the supply of cold liquid to the tank and ensure that the flow of the required temperature is output. Keep in mind that during the run through the pipes the medium may cool down somewhat. Because of this feature, the option is poorly suited for buildings of large area and number of floors.

Installation of a gas boiler with built-in boiler

When you need to organize the circulation of hot water in a private house, a scheme with an integrated heating element is better suited than with a remote double-circuit one. Why? For three reasons at once:

AMETHYST - 02 M Residential building for up to 10 people or up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Main table dispenser AquaPro 919H/RO (hot and cold water)

- heating is more stable;

- It’s more convenient to use plumbing – you can turn on all the appliances and open every tap;

- It is not difficult to create a supply of 40-60 liters of well-warm liquid (albeit gradually cooling).

But there are also disadvantages, and these are:

- large dimensions - a set of equipment and space takes up a fair amount of space and weighs a fair amount, which is not always convenient;

- high cost – implementation of such a solution is relatively expensive;

- serious associated costs - to ensure and maintain the required fluid temperature, you have to spend a lot of fuel.

In practice, these disadvantages outweigh the advantages, so this option is being implemented less and less.

Is the water supply located above or below?

The main water pipeline enters the contour of a residential building and ends with a gate valve. In-house networks provide hot water to all consumers.

Through a set of vertical pipelines (risers), the coolant is distributed among the floors. Two types of wiring are used: one-pipe and two-pipe.

The choice of scheme depends on the planning decisions of the residential building:

- The option of supplying water “from below” is used in low-rise buildings. In high-rise buildings with more than nine floors, the coolant is supplied “from above”. In this case, sufficient hot water pressure is ensured on the upper floors.

- In houses with more than eighteen floors, bottling is used “from below”, but the heating system is divided into two autonomous zones. In the upper zone, excess pressure ensures the supply of coolant to the top floors.

- In the old housing stock there are houses that do not have circulation risers - “dead-end systems”. Saving pipes comes at the cost of inconvenience: when the water supply is weak, the water cools down and you have to drain some of the water.

Installation process

Now let's see how to recirculate DHW (hot water) in the house. We remind you that all work must be carried out at the construction stage or at the stage of major renovation of the building, in parallel with the installation of the boiler. We also need to assemble and place the outline correctly, so let's decide what we need for this.

Tools and materials

- welding machine of suitable performance and configuration;

- grinder, jigsaw or other appropriate tool for cutting pipes;

- fasteners, adapters, fittings;

- plumbing winding;

- Unipak sealant or similar thread paste.

To place the load-bearing elements, it is also worth arming yourself with an impact drill, a hammer drill, and a set of drills.

Equipment

When choosing a DHW scheme with recirculation for a private home, remember that in any case you will need:

- pipes - of different sections and made of various materials, from copper to plastic, depending on the purpose and characteristics of the line;

- three-way and ball valves, valves, reversing valves and other shut-off valves;

- medium or low power pump.

High pump performance is not even desirable, because it needs to provide only a small pressure - to move the flow along the line, but not to make it run quickly. Well, the nature of the execution of communications may require additional work, for example, soldering brass connections.

Installation algorithm

The answer to the question of how to circulate hot water (DHW) in a private home is quite simple. This problem must be solved step by step - in the following order:

- mark the supporting surfaces (usually walls) according to the drawing;

- install brackets, clamps, clips and other load-bearing elements;

- cut pipes along the entire length of the future communication;

- organize the line by sequentially connecting all the necessary adapters and fittings;

- connect the pump, mixers and similar units, as well as shut-off valves;

- provide outlets for the outflow of used liquid.

If a more complex circuit is planned, deviations from the given algorithm are acceptable, but in practice they will turn out to be insignificant and will consist of adding some additional elements, for example, distributors, and flow control and metering devices.

Equipment required for network operation

A closed hot water system is a rather complex engineering and technical system and to ensure uninterrupted, and most importantly safe operation, a set of certain equipment is required.

Water flow metering unit

It is through it that water is supplied to the house water supply. A water flow meter is installed on it. In addition, the design of the unit provides for the possibility of turning off the water supply during repairs of pipeline fittings, both scheduled and emergency. The following components are installed in the water metering unit:

- magnetic or mesh coarse filter;

- taps and valves through which cold water is supplied;

- measuring instruments - pressure gauges, thermometers;

- bypass - a bypass pipeline that is used while servicing the water metering unit.

Of course, to ensure the operation of the hot water system, a pipe system is involved; it can be divided into three groups:

- bottlings;

- risers;

- carts.

Through bottlings located in the basement of the building, water moves to the risers. Through them, it is supplied directly to apartments and through supply lines to end consumers - sanitary equipment, household appliances, heated towel rails, etc. There are many layouts of pipes for each group. For example, through risers located in one apartment, water can be supplied to neighboring housing.

The diameters of the pipes are determined during the design of the building, but as a rule the following dimensions are maintained:

- Bottlings from 32 to 125 mm;

- Risers from 25 to 40 mm;

- Eyeliners within 15 - 20 mm.

When developing a project for a closed hot water system, the following materials are used:

- metal-plastic;

- pipes made of food grade stainless steel;

- galvanized pipes.

When ordering pipes, you must remember that metal-plastic pipes can be designed for different pressures and different operating temperatures. By the way, during major repairs, unscrupulous contractors install pipes that do not meet the requirements of the working documentation, the same applies to pipeline fittings.

Operation and working principle

Now let's see how the implemented hot water supply scheme with circulation should be used:

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

Floor-standing dispenser AquaPro 6207CH (cooling/heating/room temp.)

In a private home, it is recommended to keep it constantly on, although it is acceptable to turn it off at night or even for several days (in case of departure) for the sake of economy and safety; but here it should be taken into account that restarting will take time, so you will have to get up early in the morning to warm up the circuit.

In a multi-storey building, it is already necessary for the equipment to operate continuously, and automatically - residents do not have to waste their time and effort on managing it.

Private sector

What hot water supply schemes with circulation are used in cottages?

Actually, there are only two basic diagrams: with circulation through the water heater (for this it must be equipped with an additional pipe for connecting the DHW return) and with a thermal mixer. The water is driven by a small-sized pump with a wet rotor.

Closed circuit with circulation pump and boiler with three outlets

Pump for heating and hot water needs with a wet rotor

A three-way thermostatic valve allows you to implement recirculation even if in your home an electric boiler or an indirect boiler with two pipes (DHW and make-up) is responsible for heating the water.

Scheme with a conventional boiler and a three-way thermal mixer

Pump unit and piping

They are interconnected: the layout of the circuit also depends on the parameters of the supercharger. So, for example, with indirect heating, the return pipe can be connected to an additional, third outlet; otherwise, the reverse should be applied to the tee located on the cold water supply pipe, and this implies the installation of a more powerful pump.

If the circuit for connecting hot water with circulation is implemented with a standard heating element with a pair of taps, a safety group is installed, that is, one ball valve for insertion into the “cold” line and a second one for the return flow of the liquid in the cycle loop. As a result, the ambient temperature decreases only when the fence is opened, and the boiler functions as efficiently as possible.

Attention, you need to install a special pump with 1/2 or 1/4 inch threaded pipes, that is, the same size as household communications. The power of such a supercharger will be sufficient, but not high, so it will not create excessive pressure that could cause a line rupture. Leading pump manufacturing companies, such as Grundfos or Wilo, must take this point into account.

Open circuit structure

How does an open system work? It consists of a supply and return pipe, which are connected at a heating point or elevator unit, where the water is brought to 60°C. After which it is fed into the internal pipeline of the house.

The principle of operation of a dead-end network is quite simple. The circuit contains a heating device, a circulation pump that provides transportation, and a pipeline leading to the distribution points.

The open system consists of:

- pipes of various sections (with a diameter of 20 - 200 mm);

- thermometers;

- thermal insulation;

- check valves;

- pressure gauges;

- ball valves;

- gate valve;

- temperature regulators (with and without controller).

Installation options differ, they are:

- With top wiring. Implemented on under-roof technical floors in buildings with the possibility of installing water heating tanks.

- With bottom wiring. The equipment is installed in the basement, which ensures easier maintenance. However, with this method, the pressure for all floors is not the same, so booster pumps are usually installed to maintain it.

The speed of water movement is influenced by:

- the height to which water is supplied;

- dynamic pressure;

- inevitable losses.

Therefore, pressure switches are installed on pipes, and float sensors are installed in tanks. To avoid having to drain water from the entire system for repairs, the pipeline branches are equipped with shut-off valves so that the section can be temporarily cut off from the network.

Pipe system

When you want to organize hot water supply for a private house with circulation, get ready to spend money, because any scheme is relatively material-intensive to implement. Because you will need to close the circuit in a loop and properly insulate the channels in order to minimize parasitic heat leaks.

The best option would be PEX, that is, polyethylene pipes with slide-type press fittings. They need to be installed using specialized tools, and this is an additional expense, but they are much cheaper than metal-plastic or polypropylene and, most importantly, are several times more durable. Therefore, they are completely justified economically.

The procedure for laying a pipeline to implement a hot water circulation circuit is relatively simple:

- install a continuous fluid supply line to the plumbing;

- connect it sequentially to each point of consumption;

- then do not finish it, but lead it back to the heater assembly, creating a closed loop.

Any individual segment of communications should be protected from heat loss - with belt insulation made of polyethylene or, even better, rubber, since it is more dense, which is preferable when bricking up a channel. All resulting joints also need to be additionally glued with special metallized tape to prevent damage in these most vulnerable places.

Controlling water recirculation in a hot water supply system

You can organize the control process in one of three ways:

- by carrier temperature;

- by time;

- on both these parameters at once.

Any modern and high-quality pump has all the automation necessary to implement each of these methods. Often, it even boasts a “learning” function: based on statistics, it is determined when and how much liquid people consume and, in accordance with the data obtained, the time of downtime and active use is adjusted. Inexpensive models require additional attachments, such as a timer.